Engine lubricants are intricate liquids. The present higher performing engine lubricants contain a painstakingly adjusted definition of base oils, propelled added substances and thickness

A proportion of a liquid’s protection from the stream. A liquid with higher thickness streams less effectively. modifiers, each performing quite certain and crucial capacities. To function as planned, every lubricant should be painstakingly defined and tried to guarantee it performs up to or past explicit endorsement and execution necessities. The beneath gives an outline of the run of the mill segments in an engine lubricant, fortifying the multifaceted nature engaged with detailing just as understanding the particular needs the lubricant needs to perform to.

Table of Contents

Base Oil

The essential or basic liquid, more often than not a refined oil part or a chose manufactured material, into which added substances are mixed to deliver completed lubricants.

How about we begin with the base oil. The American Petroleum Institute

Programming interface. The essential oil and gaseous petrol exchange relationship in the United States. Programming interface works a deliberate permitting and affirmation program that permits engine oil suppliers to utilize the API Engine Oil Quality Marks if their items meet explicit necessities.

American Petroleum Institute. The essential oil and flammable gas exchange relationship in the United States. Programming interface works a deliberate authorizing and confirmation program that permits engine oil advertisers to utilize the API Engine Oil Quality Marks if their items meet explicit necessities. It has classified base oils into five classifications and inside every classification, base oils have a wide scope of various specialized and execution qualities. And keeping in mind that the base oil makes up most of a substantial engine lubricant (which commonly fall inside 60 to 95% of the weight), even the most elevated quality base oil alone can’t give full insurance against the impacts of warmth, the powers of shearing, the impacts of wear particles, concoction and water weakening just as consumption.

When creating added substance bundles, formulators should know about the particular base oil being utilized, as various added substance plans will be required by the attributes of each base oil.

Thickness Modifiers

Consistency modifiers are polymers explicitly intended to help control the consistency (thickness) of a lubricant over a predetermined temperature extend and working condition. As engine parts become increasingly refined, propelled polymers empower progressively productive activity, in progressively extreme situations and are basic in giving greatest proficiency, strength and insurance.

A wide scope of consistency modifier

A lubricant added substance, as a rule, a polymer, whose primary capacity is to diminish the inclination of an oil’s consistency to change with temperature. Present day VMs are execution polymers that can give extra advantages too.

innovations exist and the particular thickness modifier required is reliant upon various interrelated components including the working conditions the general lubricant needs to perform in, nearby the base oil and added substances being utilized.

Added substances

Despite the fact that the added substances make up a little piece of the volume of the lubricant, they have a major job in securing basic engine parts. The added substance bundle can contain:

1 Cleanser

A substance added to fuel or lubricant to keep engine parts clean. In engine oil plans, the most usually utilized cleansers are metallic cleansers with a hold of basicity to kill acids shaped amid burning.

Cleanser — A cleanser is a substance added to fuel or lubricant to keep engine parts clean. In engine oil plans, the most generally utilized cleansers are metallic cleansers with a save of basicity to kill acids framed amid ignition. (Looking after Cleanliness)

2 Dispersant

An added substance that helps keep strong engine oil contaminants in suspension, along these lines forestalling the arrangement of slop and varnish stores on engine parts. Dispersants are typically nonmetallic (“ashless”) and are normally utilized in mix with cleansers.

DISPERSANT — A dispersant is an added substance that suspends contaminants in the oil, anticipating slop and varnish stores on engine parts. Generally nonmetallic (“ashless”) and utilized in blend with cleansers. (Taking care of Contaminants)

3 Cancer prevention agent

Cancer prevention agent – A cell reinforcement or oxidation inhibitor is an added substance, typically joined in a moderately little extent, to moderate the oxidation of lubricants. (Limiting Oxidation)

4 Hostile to wear operator

ANTIWEAR AGENT – An antiwear operator is an added substance that works inside a plan to frame flimsy, constant movies on profoundly stacked parts to counteract metal-to-metal contact. (Decreasing Engine Wear)

5 Rubbing modifier

A lubricant added a substance that presents a rubbing diminishing film between surfaces where gentle sliding conditions happen. Grating modifiers are normally incorporated into an act added substance bundle and can be utilized in certain applications like programmed transmissions to energize the association of moving segments.

Erosion

The protection from the movement of one article over another. Grating relies upon the smoothness of the reaching surfaces, just as the power with which they are squeezed together.

MODIFIER – A grinding modifier is an added substance that connects to a surface and is utilized to lessen contact and wear when gentle sliding conditions happen. Rubbing relies upon the smoothness of the reaching surfaces, just as the power with which they are squeezed together. (Diminishing Engine Wear)

6 Foth inhibitor

Froth INHIBITOR – A froth inhibitor is an added substance that represses oil frothing in a lubricant from Lubricants Factory UAE. Froth prompts siphon cavitation or loss of lubricant stream. (Diminishing Aeration)

7 Erosion inhibitor

A lubricant added a substance that shields greased up metal surfaces from compound assault by water and different contaminants. Erosion inhibitors are regularly incorporated into an exhibition added substance bundle.

Consumption INHIBITOR – An erosion inhibitor is an added substance that shields greased up metal surfaces from synthetic assault by water or different contaminants. (Controlling Corrosion and Acids)

8 Pour point depressant

PPD. A lubricant added a substance that brings down the absolute bottom at which a lubricant streams with the goal that the lubricant can be utilized in chilly situations. PPDs are regularly excluded in an exhibition added substance bundle.

POUR POINT DEPRESSANT – A pour point depressant is an added substance used to bring down the pour point or low-temperature, low shear-rate smoothness of an oil product.(Managing Viscosity)

How to Make Your Stall Stand Out at Trade Fairs and Conventions

How to Make Your Stall Stand Out at Trade Fairs and Conventions 7 Key Issues About Supplier Audits

7 Key Issues About Supplier Audits Precisely Ground Flour from Domestic Flour Mills is the Best for Indian Foods

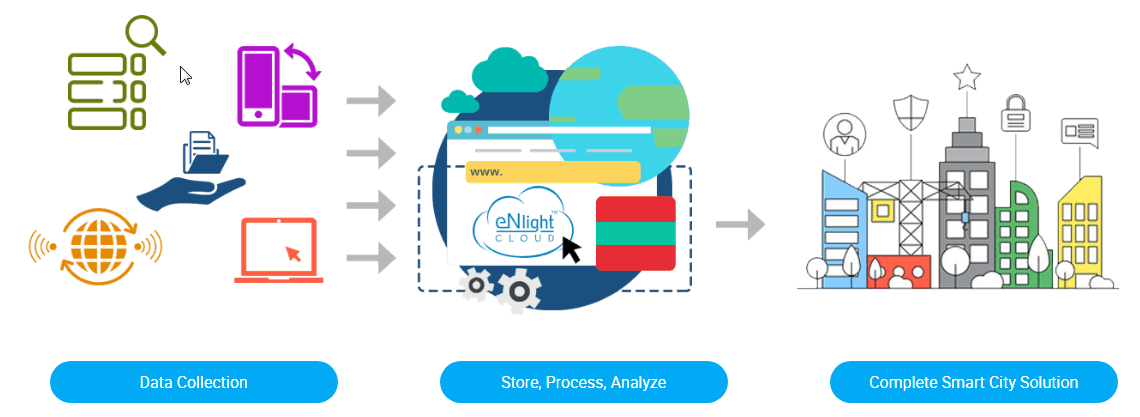

Precisely Ground Flour from Domestic Flour Mills is the Best for Indian Foods How Big Data has the biggest impact in Smart Cities

How Big Data has the biggest impact in Smart Cities